Shot cleaning units for evenly cleaning heat exchangers

One of the most important criteria for using heat exchangers is efficient cleaning. Only optimum heat transfer guarantees the maximum effectiveness and economic efficiency of modern boiler systems.

The problem

Dust and deposits on heating surfaces seriously inhibit heat transfer. Shot cleaning units are designed to remove these deposits.

The solution

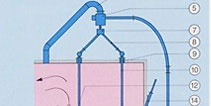

In this cleaning system, steel balls, known as “shots”, are introduced at the top of the heat exchanger and then fall through the heat exchanger into the ash hopper. On the way down, the shots bounce backwards and forwards between the pipes, removing dust and deposits from all sides of the pipe walls as they rebound off the individual pipes. Underneath the ash hopper, the dust, shots and large pieces of debris are separated via a screening machine. The dust and debris are conveyed into the de-ashing unit of the boiler system, while the shots fall into the shot storage tank. A fan transports the shots back up to the top for another cleaning cycle.

At FGW GmbH, great attention is paid to precisely adjusting the circulation time and operating frequency of the cleaning unit to the level and type of soiling to guarantee optimum heating surface cleaning. State-of-the art monitoring devices ensure trouble-free and low maintenance operation.

Environmentally friendly process

The shot system is an environmentally friendly method of cleaning which produces no toxic industrial effluent. Furthermore, this method has proven its effectiveness in numerous systems in Germany and other countries. Cleaning is possible during system operation and at temperatures of up to 1000 degrees Celsius.

Intensive fields of application

Shot cleaning units keep heat exchangers clean behind industrial firing systems that use solid and liquid fuels, such as incinerators, biomass boilers, gas fired systems, air heaters behind cupolas, oil heaters, liquor recovery boilers, heat recovery systems on ships, diesel heat recovery boilers and many other types of heat recovery boilers, thereby maintaining the required level of efficiency.

FGW GmbH attends to over 980 shot cleaning units worldwide and is in a position to supply original spare parts even for older shot cleaning units.

Profit from our many years of experience: tried-and-tested methods with proven efficient results as well as innovative modern solutions.

We provide a complete range of services for professional system cleaning. Further information is available here: